Bead mills are commonly used in the production of pesticide raw materials, which require control over the particle size and shape to ensure the quality and effectiveness of the final product. This calls for efficient and precise particle grinding equipment, and bead mills are well-suited for this purpose. ALLWIN’s bead mill can grind pesticide raw materials quickly and uniformly, ensuring the stability of particle size and shape, thus improving the quality and effectiveness of pesticides.

ALLWIN showcases bead mill at Hangzhou Pesticide Exhibition

From March 20th to 22nd, ALLWIN participated in the 22nd National Pesticide Exchange Conference and Pesticide Product Exhibition held by the China Pesticide Association in Hangzhou. At the exhibition, we showcased our bead mill products and shared their applications in the pesticide industry.

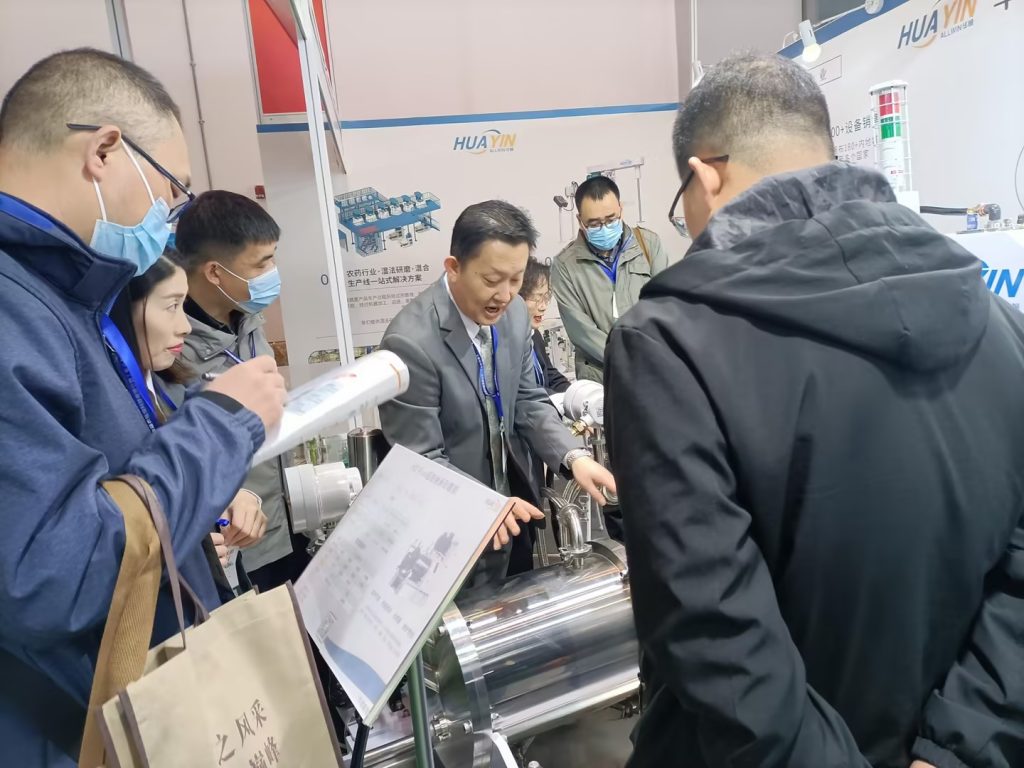

The bead mill attracts attention at the exhibition, grinding pesticide raw materials into fine particles quickly

The ground particles are uniform in size, with stable and reliable quality, meeting the standard requirements for pesticide formulations. This can improve the efficiency of pesticide formulation and reduce production costs while also enhancing the solubility and uniformity of pesticides, thereby improving their effectiveness.

Many customers visit ALLWIN’s booth for consultation Inquiring about equipment performance and technical aspects

The long-term stable operation of the bead mill ensures production continuity and meets the grinding process requirements of large-scale pesticide formulation production, thereby ensuring production efficiency and stability.

The equipment also caught the attention of foreign customers, who showed a keen interest in its cost-effectiveness.

With reasonable prices and product performance and quality meeting customer requirements, the equipment can satisfy the needs of different customers, reduce maintenance costs for pesticide companies, and improve production efficiency and stability.

Recommended Equipments For Pesticide Industry

HZ PLUS Super-Fine Nano Bead Mill

Model: 30L 50L 100L 150L 250L 400L 500L

Grinding Media Diameter: 0.1mm—2.5mm

Grinding fineness: Submicron to Nanometer level

Advantages: stable and reliable, efficient and energy-saving, no blockage in discharging

High-Speed Disperser Mixer

1) Multiple models are available

1) Multiple models are available

2) Parts can be customized

3) Sand mill machine supporting products

4) Pre-dispersion grinding

5) Hydraulic lifting

6) Safe operation