Allwin’s advanced industrial mill grinder machines and systems cater to a wide range of production needs across various industries.

Allwin has engineered and crafted a series of wet grinding machinery, dedicated for producing exceptional blends through advanced grinding and dispersion techniques.

Designed for precision grinding and dispersion of solid-liquid mixtures, reducing particle sizes to the range of 300 microns to 100 nanometers.

An industrial equipment specialized in mixing, stirring, and dispersing liquids, powders, or viscous materials.

Innovative solution in the Water Chillers, Grinding Media Automatic Loading Machines, Diaphragm Pumps, Filters, Filling Machines, Rotor Pumps, and Homogenizers.

The design is aimed at effectively blending liquids or particulate materials within the container, achieving uniformity and consistency.

Durable and wear-resistant ceramic material. Renowned for its exceptional hardness, toughness, and chemical inertness, zirconia grinding media is a popular choice.

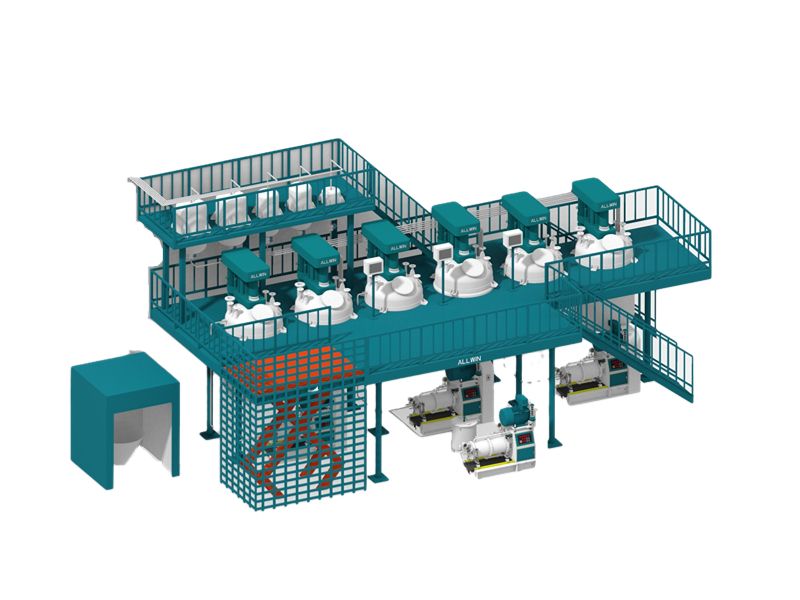

The entire process from production workflow design, equipment supply, automation control systems, to on-site debugging and support services.

Grinding requirements differ per sphere as different particle fineness determines the composition of a product, such as pharmaceutical, paints, and other chemical products.

As such, Allwin provides bespoke solutions based on careful and attentive research and realized with our self-developed nanotechnology.

For specific industrial requirements and standards, our experts are capable of designing and producing industrial grinding mills to help get higher production capability.

Our senior engineer Yongqi Wang designed the first bead mill in China and drafted industrial standards for sand mill production in China. With these technical understanding, we rise in the industry as specialists in creating solutions that are more responsive and high-performance to any industry’s needs than our peers.

Our services begin with experience and end with innovation.

We have sold more than 10,000 equipments, serving 180+ Chinese cities and exporting products to multiple countries.

Covering Battery Materials, Ceramics, Nanomaterials, Coatings, MLCC/LTCC, Pharmaceuticals, Beauty & Skincare, Food, Titanium Dioxide, Paper, Inks, Agrochemicals, Graphene, Metals, Non-Metallic Minerals and more.

Experience 30% more energy efficiency! Unlike traditional bead mills, ours comes with a low-energy motor. Same production power, but with a whopping 30% less energy consumption for superior savings.

Mastering wet grinding since 1993, Mr. Wang Yongqi, a co-founder and one of the architects behind China's first bead mill in 1967.

Our bead mill excels at grinding materials to super-small sizes, from Micrometers to Nanometers. Precision that meets your demanding standards.

The entire process from production workflow design, equipment supply, automation control systems, to on-site debugging and support services.

From consulting to production and after-sales services, you can count on our professional experts and hassle-free processes.

Experience excellence as our valued client.

Allwin’s blogs are where you’ll find the latest topics and the most professional insights from our wet grinding machine specialists.

9am-5pm (GMT+8)